It is a critical to your health and safety when operating a vehicle. With a well-maintained A/C system, exposure to dangerous heat and driving risks can be avoided.

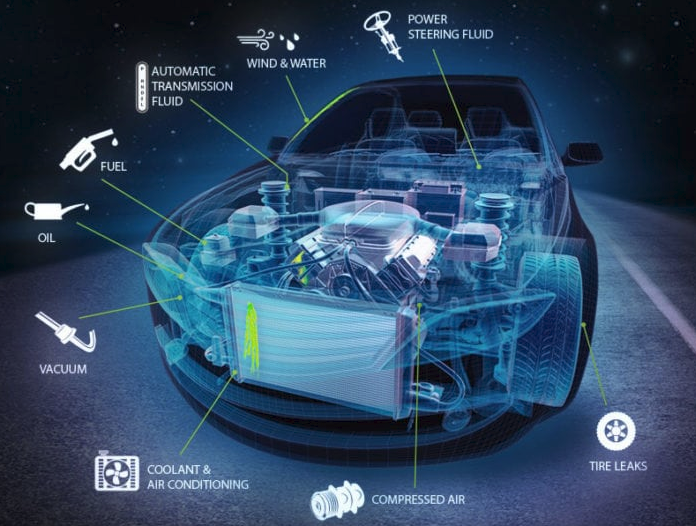

There are steps anyone can take to keep vehicle systems in good condition. There are car issues that require professional help. But there are things a driver can do to maintain and identify vehicle problems early on.

We should first learn about the major components of your air conditioning system. Diagnosing a slow leak situation remains challenging for even the most skilled technicians. You will need an abundant amount of patience to fix this type of AC problems. If there is a leak in the AC condenser, the refrigerant will escape and stress the system. A lack of refrigerant reduces the cooling performance of the AC system and damages the components. When a leak is present, moisture can also make its way into the unit. Mold and mildew can form and interfere with normal operation. Refrigerant contamination causes significant wear-and-tear.

A quick review of how the ac compressor works on an older car will help us understand why the problem is so diabolical. Once compressors get over 150,000 miles usage, it’s just a matter of time until they develop problems. If you’re lucky, the compressor will have external problems requiring replacement before the inside deteriorates.

Typically, the reason why an internal failure is such a big problem is that metal chips break off and are pushed throughout the entire AC system. This is why an internal compressor failure is the worst AC problem. Mechanics do their best to flush the system with a specialized cleaner. Despite their best efforts, just a few chips hiding in the corner of a condenser assembly can work its way loose and cause repeat problems. Not only is a compressor replacement expensive from an auto part and labor point of view, but it often leads to additional visits to the mechanic to fix ongoing problems

Sunlonge SL3200 is fluorescent UV dye for the oil system. The application is quite easy and suitable for all the oil systems. Just add the SL3200 UV dye to the system and circulated. Then the dye will collect at all leak sites. The system will be inspected with a UV light. You can find the precious location of every leak with a bright glow. The UV dye can remain in the system and does not affect the components or performance.

Following our simple maintenance tip and using UV dye for preventative maintenance will reduce the chance of total component failure. Cos it is much easier and cheaper to find a small leak before it turns into a bigger problem.

CN

CN