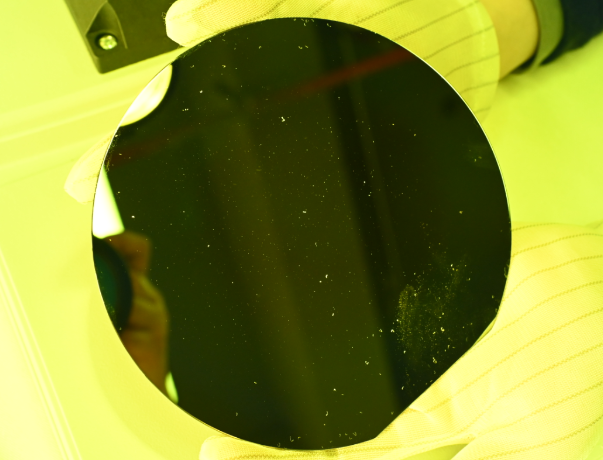

Why Sunlonge SL8900 will be a better wafer inspection lamp?

After consulting lots of professional technician and end semiconductor manufacturers, Sunlonge developed the SL8900 wafer inspection lamp, aiming to offer a better and more reliable solution for the wafer surface inspection service. We are quite sure that SL8900 can be a new and better option for wafer inspection than the traditional halogen (Mercury-vapor) lamp. The reasons are mainly listed as following:

1) 2 in 1 device.

As we know, the traditional halogen lamp can only perform with one wavelength. Frankly speaking, halogen lamp may be good for some surface inspection service due to the high illuminance. However, with just one wavelength, it can not cover all surface inspection demand.

Sunlonge SL8900 is with 1 pcs 30W white LED light source. With an external filter, the wavelength can be amber-green multiple wavelength. So you can understand that SL8900 is a 2 in1 wafer inspection lamp, 2 wavelength into 1 device. Then with SL8900, you can cover almost all the wafer surface inspection service, eg particle, dust, stain/efforts and so on. It can perform much better performance than the single wavelength halogen lamp.

2) More secure and environment-friendly.

Secure and environment-protection is critical factor in today’s industrial application. We need to seek a better future for our next generation. SL8900 is with just 1 pcs 30W LED light source. With the transfer of optical lens, the light illuminance can be up to 400 000 lux at 30CM distance, equivalent with the 200-300W halogen lamp. With LED technology, SL8900 runs much cooler than halogen and traditional mercury-vapor lamps to help keep operators and inspection booths cool. Meanwhile, SL8900 is more environment-friendly as well due to the LED features.

3) Technology trend.

Frankly speaking, halogen lamp is with the outdated halogen technology. The mercury-vapor lamp is mainly banned by the most developed countries due to the high risky and polluting the environment. After 10 years of continuous working, more and more customers realize its insufficient, lack of reliability and generating a lot of heat. LED is the trend in the industry and can resolve these issues. The lifespan of LED can last at least 30 000H. So we are quite sure more and more customers will realize that LED will be the trend in this industry and will select the LED as their main inspection tool in the near future.

By carefully considering the customer’s real demand before investing in our wafer inspection lamp, That is why Sunlonge SL8900 has approved by many heavy semiconductor manufacturers in China. Due to the responsibility to our customers, Sunlonge will keep developing more and more industrial inspection lamps to make your inspection service faster and more efficient.

CN

CN