Major and minor infrastructures, tools, and equipment in almost every industry make use of fastener for the purpose of holding components together and increasing their ultimate strength. While vital, fasteners are often overlooked during NDT of these components. Without a proper fastener inspection procedure in place, failure may go unnoticed and can have severe consequences resulting in risk to operations, and in some cases, human lives. To avoid these risks, a thorough NDT inspection could help identify any damages to the fasteners.

Many industries use penetrant testing (PT) and magnetic particle inspection (MPT) as the primary methods of inspecting fasteners. The competent capabilities of these methods allow the strength of fasteners and the structural integrity of components to be thoroughly tested.

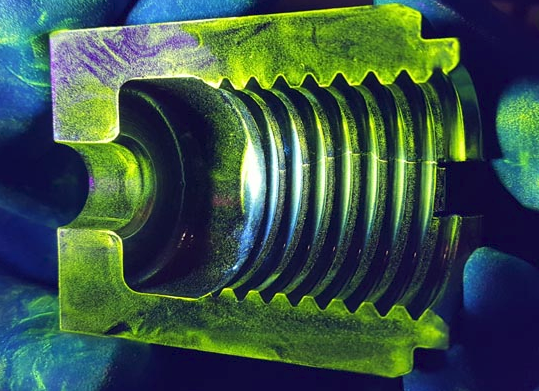

Fastener used in industries include nuts, bolts and other similar types of hardware that can mechanically join the parts together. In manufacturing or infrastructural operations, these fasteners can also be exposed to different types of loads. When exposed to extreme loads, fasteners can be the subject of fatigue failures. Even the environmental issues can give rise to a number of flaws in the fasteners. This may include cracking, corrosion, or other discontinuities. Realizing the extent of these flaws in the early stage is important to prevent potential damage to the structure or equipment.can use our SL8904AR NDT LAMP, SL8904-Aerospace RRES90061 Meets Rolls-Royce RRES 90061 Requirements ASTM E1417, ASTM E1444, ASTM E 709, ASTM E2297, ASTM E3022 compliant Meets ASTM UV-A intensity and wavelength specifications for FPI and MPI.

With NDT, technician can establish and ideal fastener inspection procedure to determine the location, size, and overall extent of the flaw before the structure suffers mechanical failure.

Flaws can be difficult to visually detect or hidden. Thus, for thorough and accurate inspection of fasteners, industries use MPT as the primary NDT method.

Different industries and applications require different types of fasteners, thus, various MPT and PT are available to fulfill the inspection needs. With the right tools, industries can develop a detailed fastener inspection procedure and be confident in the accuracy of inspection results. With the ability to identify even the tiniest flaws, industries can focus on potential damage prevention and ensure operational productivity.

CN

CN