Why UV intensity of 5,000 μW / cm² or less is optimal for penetrant testing?

In the fluorescent penetrant testing and the fluorescent magnetic particle flaw detection testing, various standards require that the UV intensity of the test surface when irradiated with black light be 1,000 μW / cm² or more. This is because if this is not met, the scratch may be overlooked due to the weak UV irradiation.

On the other hand, the stronger the ultraviolet irradiates, the brighter the fluorescent material fluoresces. For this reason, it is generally considered that black light, which is with higher UV intensity, has higher performance and is more suitable for inspection.

However, the following two standards state that the UV irradiation on the test surface cannot exceed 5,000 μW / cm² in the fluorescent penetrant testing.

Why shouldn't the test surface be exposed to high levels of UV light above 5,000 μW / cm²? There are two reasons:

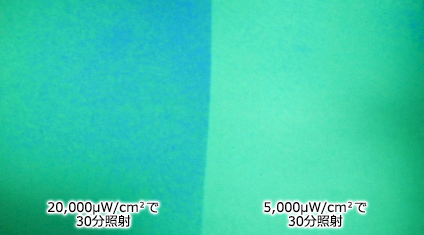

One is the deterioration of fluorescent material due to ultraviolet. Irradiation with strong UV light for a long time may deteriorate the fluorescent material and weaken the reaction to UV light. Check the results of continuous irradiation for 30 minutes at 5,000 μW / cm² and 20,000 μW / cm², respectively. It can be seen that the reaction of the fluorescent reaction is weakened in the area irradiated with 20,000 μW / cm².

Another reason is to prevent glare. Black light for non-destructive testing irradiates ultraviolet rays in the UV-A range of 320 to 400 nm centered on 365 nm. It is generally said that ultraviolet cannot be seen by the human eye, but of course there are individual differences and age differences, and some people can perceive ultraviolet of 390 NM and 380 NM. For them, the glare on the observation surface caused by high levels of UV radiation can make scratches hard to see and can be overlooked.

By irradiating with stronger UV intensity, you can certainly observe clear scratch patterns. However, at the same time, it may not be possible to observe an appropriate scratch pattern by deteriorating the fluorescent agent, weakening the reaction to ultraviolet, and causing glare on the observation surface.

It is necessary to avoid exposing the test surface to high levels of UV intensity above 5,000 μW / cm², and many UV lights sold by Sunlonge for non-destructive testing, are 5,000 μW / cm² at 38 cm distances, to help provide a more reliable yet cost effective inspection service for the customers.

CN

CN