Due to strength in technology, Sunlonge played an important role in the surface inspection field for the semiconductor industry. Today Sunlonge can provide a full set series solution for different customers with different demand. Now aiming to offer a more reliable tool for the wafer inspection service, Sunlonge recently release the new SL8100 model, which we believe will become a much more powerful tool for the high-end wafer inspection demand.

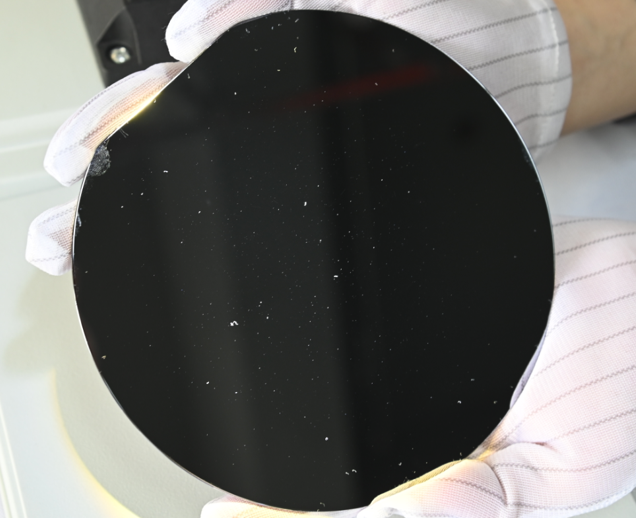

Designed for high end professional wafer surface inspection, Sunlonge SL8100 can improve the quality and flexibility by offering 350 000 lux super high illuminance with wide coverage 8 inch at 12 inch distance. With Sunlonge SL8100, the inspector can easily detect and locate the visible flaws on the wafer surface during the inspection pros. Here is the reason as following:

1. Super high illuminance

Sunlonge SL8100 is with 1 pcs 35W white light LED light source. With the customize-design optical lens, the illuminance can be up to 350 000 lux at 30CM distance, which is equivalent with the traditional 200W mercury-vapor lamp. The super high illuminance can detect and highlight all the cracks on the wafer surface, eg particle, dust, contamination and so on. Moreover, now with our customize-design filter, SL8100 can perform 2 wavelength, 6000K white light or green-yellow multiple light. Both are sensitive light source to human vision. It can definitely perform better than the traditional mercury-vapor lamp.

2. Long lifespan

Nowadays, the mercury-vapor lamp is mainly banned by most developed countries due to the risky and polluting the environment. As for the halogen lamp, the bulb can be running for hundred hours. Then you need to replace a new bulb frequently. During the past 10 years of continuous working, a lot of customers realize the halogen lamp’s insufficient, lack of reliability and generating a lot of heat. LED is the answer to the industry. The lifespan of LED can last at least 30 000H. These days, more and more customers realize the advantage of LED and select it as the main inspection tool.

3. Easy and friendly working environment.

Environment friendly is more and more important for the human sustainable development. We also need to find a better way for our next generation. Due to the LED technology, SL8100 is running much cooler than the halogen and mercury vapor lamps. Thus, the operators can be stay in an easy inspection booth. The low power consumption is more environment friendly.

Due to our strength in technology, Sunlonge will keep developing more high-performance industrial inspection lamp to our customers. SL8100 is the least one, but not the last one. We will all see that Sunlonge keep leading the way in the semiconductor inspection field.

CN

CN