Why the UV LED lamps need to be with UV filters? Cos UV filters can block the visible light emission and increase contrast of fluorescent indications. Then the NDT inspection can be much easier and more reliable.

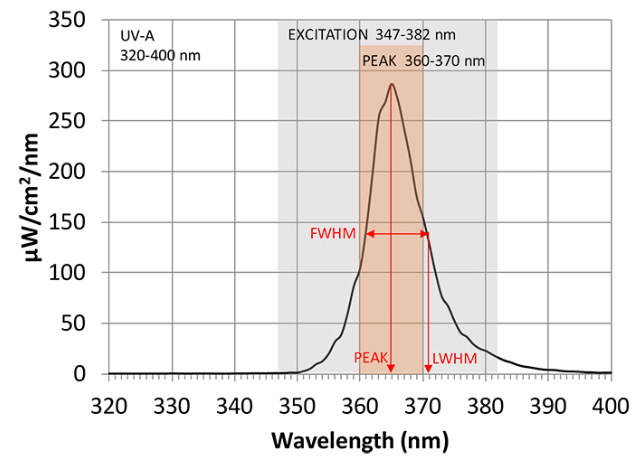

From the technical point of view, we usually defines UV-A as 315-400NM, and visible light as 400-780NM. The emission spectrum of an UV-A LED is a single peak in the 360-370NM range. But this is not a tight, sharp peak, and at the tail end of the emission spectrum you get measurable emission above 400NM.

Compared to the UV-A peak, the emission above 400NM can be a very small amount of light. But, it is visible as a deep violet glow on the surface. In the real inspection, it may affect the result and diminish the contrast.

Using a calibrated spectroradiometer, tail emissions can be measured and characterized by the UV lamp manufacturer. However, the standard NDT visible light meters which are typically used to check ambient light in an inspection area are not capable of accurately measuring tail emissions; abnormally high reading may be seen even when the actual visible light levels are below 2 FC candles or 20 lux.

Instead of creating an all-new method for fluorescent NDT practitioners to monitor their UV LED lamps, the ASTM E3022 and RRES90061 standard both require the UV lamp manufacturer to include a UV-A pass filter in each UV LED lamps. The pass filter acts to remove tail emissions above 400NM, which eliminates the accuracy issue with NDT visible light meters.

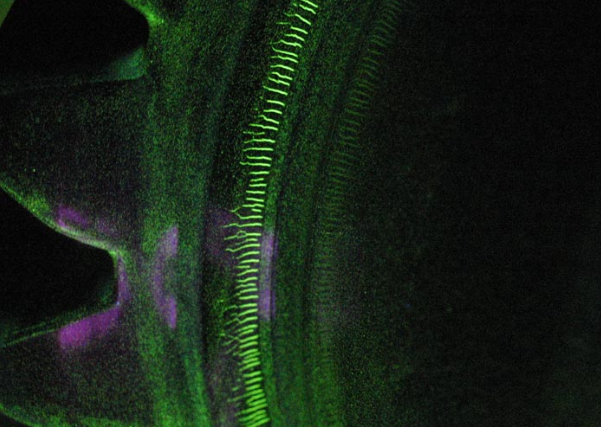

Since tail emission is visible as deep violet light, adding the UV-A pass filter eliminates the glare and makes the background of the part surface darker. This increases contrast between fluorescent indication and the darkened part surface when using fluorescent magnetic particle or penetrant techniques.

Glare can also mask small indications, and the inspector may need to reposition the part multiple times to view the entire surface. Elimination of glare simplifies part handling and save time during inspection.

In high volume production, small changes can multiply into large improvements. Faster detection means more parts inspected during a shift. A few seconds of improvement can mean the difference between NDT acting as a bottleneck and smooth-running operations.

Now Sunlonge developed the full set of series aerospace version(ARs) UV LED lamps for customers with high end NDT demand. The ARs are manufactured with the UV pass filters in according with the AST ME 3022 and RRES 90061 requirement. The tail emission can be limited to less than 5 lux with UV-A pass filter. Sunlonge is always make efforts to offer more reliable UV LED lamps to the NDT field customers.

CN

CN