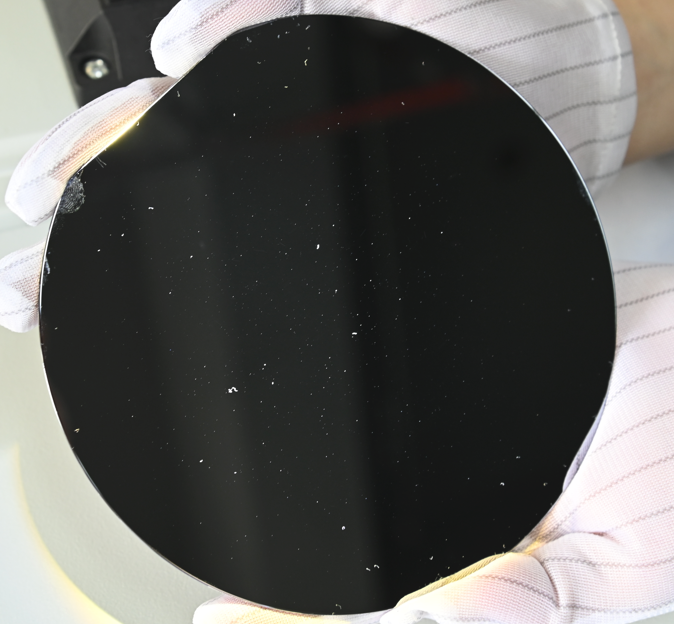

We know these days the semi-conductor industry is being more and more important to our industry. The wafer inspection lamp, the device to detect the defects on the wafer, is also being challenging to the industry.

To improve the yield and efficiency of wafer inspection, Sunlonge developed the SL8500 series wafer inspection lamp for the semi-conductor field. Due to the flexibility and stability, SL8500 series is approved by many heavy semi-conductor manufacturers in the field. Compared with the halogen lamps, even mercury vapor lamps, SL8500 is with a lot of difference.

1) Wavelength

Wavelength is important during the wafer inspection process. Wafer inspection is usually with a special wavelength to detect the defects. The halogen lamps is usually with 3000K white light, eg Sena 185. Other brands are with 525NM green light. Due to our filter technology, the SL8500 can perform multiple wavelength,6000k white light, 500-600NM amber green and so on. We can also customize the SL8500 lamp with other wavelength according to customer demand. The lamp with multiple wavelength can cover almost all the demand for wafer surface inspection.

2) Lifespan

Halogen lamps, like Sena 185LE, usually can run for 500H. Then you need to replace the new bulb, not to mention the mercury vapor lamp. And Sunlonge SL8500 is with the newest LED technology. We know LED features super long lifespan, up to 30 000H. That means once you have the SL8500 lamp. The lamp can be running for without extra cost to be paid. SL8500 can improve a lot on the efficiency and save a lot on the cost.

Light uniformity is the key factor to differentiate the industrial lamp from the regular lamp. Regular lamp is with 50%, or 55% light uniformity at most. The wafer inspection lamps are usually with 80% high light uniformity. Then it can detect the minimal size defects on wafer surface.

For wafer surface inspection, a wafer inspection lamp need to be with 100 000 lux at 30CM distance. Then the lamp can fulfill the request for wafer inspection. SL8500 series, is with 1 pcs 20W LED light source, due to the customized optical lens, the final illuminance can be up to 150 000 lux at 30CM distance. Now SL8500 can detect the defects at minimal 1um size on the wafer surface.

Besides the SL8500 series, Sunlonge now is having multiple solution for wafer surface customers. We will continue to work closely with our partner in this field and offer more and more reliable device for customers in the semi-conductor industry, to have a win-win side.

CN

CN