Nondestructive testing or NDT, is important to the auto industry. The NDT can be used for quality control and engineering. The NDT is with a variety of non-destructive technology used to evaluate the product properties, components, and look for material cracks. Sunlonge as the leading supplier in NDT field, is serving the vehicle industry for over than 15 years. In that long experience with the heavy vehicle suppliers, we understood how NDT is important to the vehicle industry and methods are applied.

Liquid penetrant testing

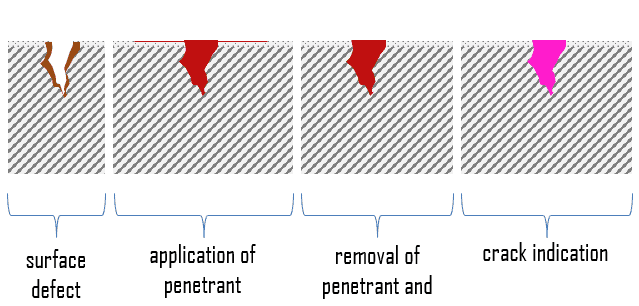

Liquid penetrant testing (LPT), also called penetrant testing, is to inspection surface breaking defects in non-holes material. The defects include slight cracks, porosity on in-service components. This is done by the coloring penetrant fluid. The liquid penetrates into the defect existing on the surface of the material. For the vehicle field, the steering spindles, aluminum suspension parts are specific applications.

Leak detection service

Some may regard the leak detection as another method of penetrant testing. The fluorescent UV dye is used to detect and locate the leaks in the systems, eg, holding tanks, tanks, pipe systems or hydraulic systems. The process is easy and simple, just add the dye into the system and let the system run for a while. Then scan the whole system with the UV lights. All leaks are glowing brightly. For the vehicle industry, the specific application includes the water and oil tank leak detection, the engine leak detection and so on.

Magnetic particle testing

Magnetic particle testing (MPT) is an NDT process for detecting surface and slightly subsurface discontinuities in ferromagnetic materials. With the magnetic yoke kit, the ferromagnetic material is magnetized and there is certain cracking on the surface of the component, a certain leakage magnetic field is formed on the surface of the components. That magnetic field is detected by a magnet-sensitive element, obtaining the location and the characteristics of the defects. For the vehicle industry, the crankshaft and ball joints are specific applications.

These years, with the development of technology and computer technology, NDT technology is also constantly changing and evolving its testing procedures and methods. However, the absolute need for NDT in the vehicle industry. As the key player in this field, Sunlonge will keep offering high quality NDT products to you all, hope to create a win-win side for both of us all.

CN

CN