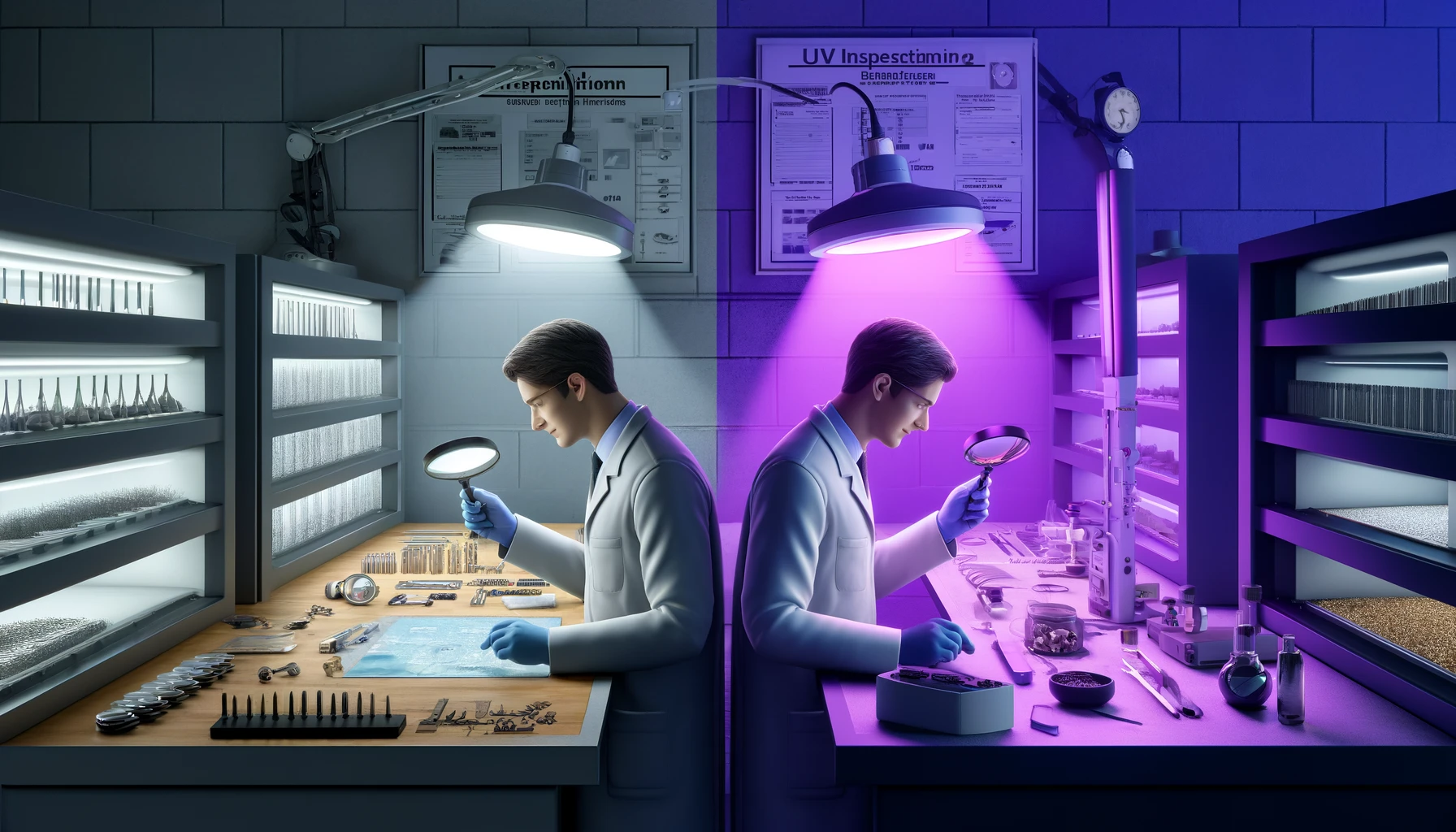

Have you ever wondered about the tools and methods that can truly make a difference? One innovative technology that has been turning heads in recent years is the use of UV (ultraviolet) inspection lamps. What unique benefit does this tool offer? These specialized tools offer a unique and data-driven approach to inspection. Thus, they provide businesses with a compelling alternative to traditional inspection methods.

Let’s look at the comparative analysis of UV inspection lamps and traditional inspection techniques. This article will help uncover the profound impact these advanced tools can have on the overall effectiveness of an organization’s quality control processes.

The Power of UV Light

At the heart of UV inspection lamps lies the remarkable ability of ultraviolet light to uncover defects, contaminants. These lamps can help uncover other flaws that often go undetected under normal lighting conditions. According to a comprehensive study published in the International Journal of Engineering Research and Applications, UV inspection lamps can identify up to 30% more defects compared to traditional visual inspection methods.

Why does this property make the lamp stand out? This enhanced detection capability is particularly beneficial in industries where even the slightest imperfection can have significant consequences. It can have consequences like automotive manufacturing, aerospace, and medical device production. Leveraging these unique properties of UV light, these lamps can effectively identify a wide range of issues, including cracks, scratches, and the presence of foreign materials.

Increased Efficiency and Consistency

Besides their superior detection capabilities, UV inspection lamps also offer a significant improvement in efficiency and consistency than traditional inspection methods. An International Journal of Production Research study found that the use of UV inspection lamps can reduce inspection time by up to 20% compared to manual visual inspection.

This increased efficiency is largely due to the ability of UV lamps to quickly and accurately scan larger surface areas. It helps to eliminate the need for meticulous, time-consuming manual inspections. This streamlined approach not only enhances productivity but also reduces the risk of human error and inconsistencies that can arise from relying solely on the human eye.

Achieving Standardization and Objectivity

UV inspection lamps provide a more standardized and objective approach to quality control. Unlike human inspectors who may be subject to fatigue, biases, or individual variations in perception, UV lamps offer a consistent and repeatable inspection process. This consistency can lead to more reliable and accurate data.

Quantifying the Advantages: A Statistical Perspective

Let’s consider a real-world case study to better understand the tangible benefits of UV inspection lamps. In a research project conducted by the Journal of Manufacturing Systems, researchers compared the performance of UV inspection lamps and traditional visual inspection methods in detecting defects on automotive components.

The results of the study were compelling. The UV inspection lamps demonstrated a defect detection rate of 95%, significantly outperforming the traditional visual inspection method, which had a detection rate of only 75%. In addition, the UV inspection process was found to be 18% faster on average, further highlighting the efficiency gains associated with this technology.

Statistical Significance and Implications

These statistical findings underscore the significant advantages that UV inspection lamps can offer over traditional inspection methods. Leveraging the unique properties of ultraviolet light, businesses can enhance their quality control processes, reduce the risk of costly defects, and improve customer satisfaction and brand reputation.

Maximizing the Impact: Factors to Consider

Ensuring Optimal Implementation

While the data-driven advantages of UV inspection lamps are clear, it’s important to note that the effectiveness of this technology can be influenced by various factors. The specific application and the training and expertise of the operators all play a crucial role in determining the optimal implementation and integration of UV inspection lamps.

Holistic Approach to Integration

To ensure the successful adoption of UV inspection lamps, you should carefully evaluate your specific needs and requirements. What does this process of evaluation involve? This may involve conducting pilot studies, assessing the compatibility with existing processes, and providing comprehensive training to the inspection team.

Conclusion

In this ever-changing world of quality control, the decision to adopt the right tools and methods can have a profound impact on an organization’s success. The above comparative analysis has demonstrated the compelling case for incorporating UV inspection lamps into quality control strategies. Leveraging the enhanced detection capabilities, increased efficiency, and improved consistency of UV inspection lamps, you can revolutionize your quality control practices.

With these, you can enhance product reliability, and ultimately, build stronger customer trust and loyalty. As the industry continues to evolve, adopting innovative technologies like UV inspection lamps will be a key driver of progress and success in the years to come.

CN

CN