Non-destructive testing plays a vital role in most industries. NDT in the oil and gas industry is critical for both the integrity of equipment and the safety of petroleum refining and extraction operations. Keeping potentially hazardous chemicals and fluids safely contained within pipes and pressure vessels means careful inspection of welds and metals for flaws and corrosion using ultrasonic and eddy current NDT testing solutions.

It plays a role in many parts of the oil and gas industry. Running a safe, efficient, and profitable petroleum extraction operation on land or offshore requires effective ultrasonic and eddy current oil and gas upstream solutions.

NDT technologies are being improved upon all the time with innovations in instrumentation, probes, and software. Keeping abreast of these innovations can help oil and gas producers in all phases of the production cycle improve the accuracy and speed of their NDT inspection of welds, pipes, and pressure and storage vessels. Improving production efficiency while ensuring the safety and reliability of their operations.

Developments in technology are opening up new NDT techniques for both ultrasonic and eddy current NDT in the Oil and Gas Industry. New instruments and improvements to existing instruments are being developed. These innovative solutions allow more accurate inspection of critical oil and gas infrastructure with a greater probability of the detection of discontinuities in welds and materials.

NDT plays a crucial role in ensuring quality assurance and asset integrity management in the Oil & Gas industry. It enables the identification and evaluation of defects, corrosion, and structural irregularities in equipment, pipelines, and infrastructure, thereby reducing the risks associated with catastrophic failures and environmental hazards. Here are the most commonly used NDT methods in oil and gas industry.

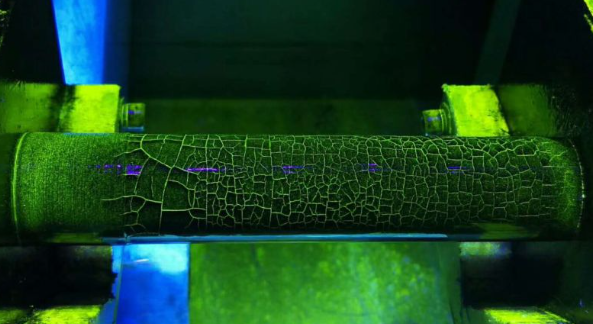

Magnetic Particle Testing (MPT):

Detects surface and near-surface defects in ferromagnetic materials using magnetic fields and visible or fluorescent particles, commonly applied in inspecting welds, valves, and pipelines.

Dye Penetrant Testing (DPT):

Identifies surface-breaking defects by applying liquid penetrants that seep into flaws, highlighted by developers, suitable for inspecting welds, castings, and machined components.

In the oil and gas industry, where safety, reliability and efficiency are paramount. NDT, particularly MPT and DPT has emerged as a crucial tool. NDT plays a pivotal tole in ensuring the integrity of equipment, As for the leading player in the filed, Sunlonge keep offering reliable NDT tools for the customer in the filed. We will be working with our partners to make NDT process more smooth and fluent.

CN

CN