Food safety has always been a primary concern in the food processing industry, and with the increasing demand for higher standards, traditional inspection methods sometimes fall short. Many contaminants, bacteria, and foreign substances are invisible under regular lighting, posing significant risks to consumer health. This is where UV inspection lamps come into play. By utilizing ultraviolet (UV) light, these lamps reveal substances that are otherwise undetectable, providing a significant tool for ensuring the safety and quality of food products.

What Are UV Inspection Lamps?

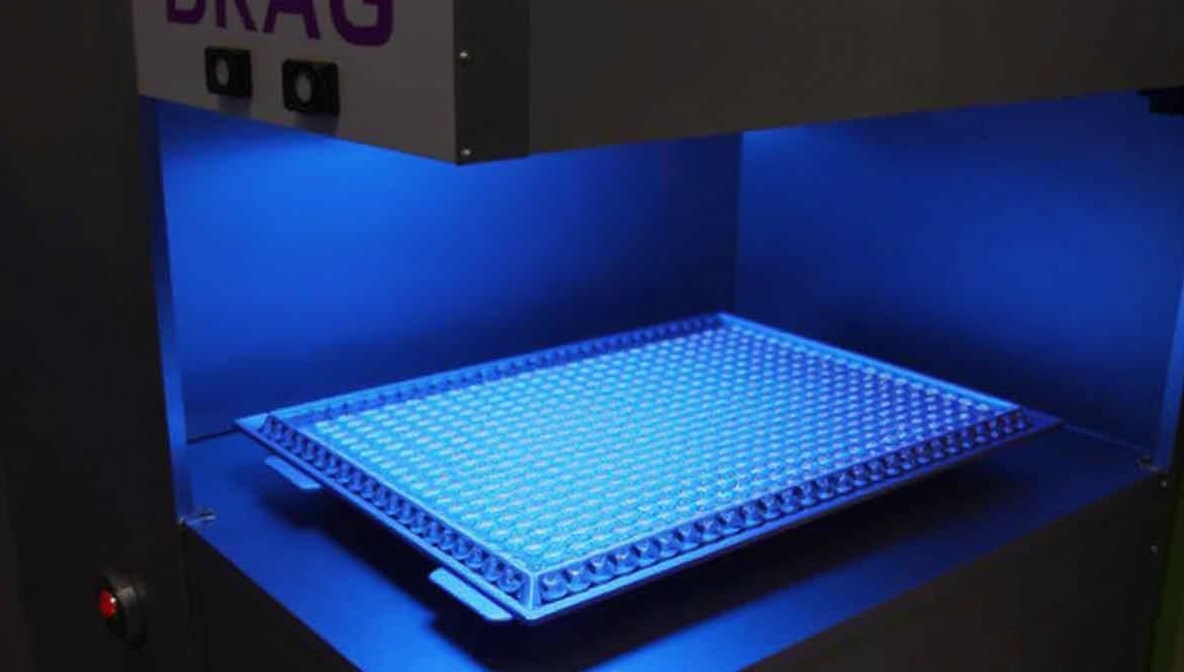

UV inspection lamps are devices that emit ultraviolet light, typically in the UV-A spectrum. These lamps are used to detect contaminants on food surfaces, equipment, and packaging. UV light has a shorter wavelength than visible light, which means it can illuminate substances that fluoresce, or glow, under its rays. This property allows workers to detect microorganisms, residues, and foreign particles that are invisible to the naked eye.

The Role of UV Inspection Lamps in Food Safety

In the food industry, UV inspection lamps are crucial tools for quality control and contamination detection. They serve a variety of purposes, from detecting bacteria and mold to ensuring cleanliness in production environments. Below are some of the key applications of UV inspection lamps in food processing:

- Detecting Bacteria and Microorganisms

UV inspection lamps help identify harmful bacteria and microorganisms that might otherwise go unnoticed. Some bacteria, like Salmonella or E. coli, can fluoresce under UV light, making them visible. This allows food safety personnel to detect bacteria at early stages before it causes an outbreak.

- Identifying Foreign Particles

Foreign particles such as dust, hair, or packaging debris can easily contaminate food products during processing. UV inspection lamps help reveal these foreign substances by making them visible under UV illumination. Identifying such particles is crucial to maintaining product integrity and ensuring that the food is safe for consumption.

- Ensuring Cleanliness of Equipment and Surfaces

UV inspection lamps are widely used to check the cleanliness of food processing equipment, workstations, and surfaces. These lamps help detect residues from cleaning agents or leftover food particles, ensuring that everything is sanitized properly before the next batch of food is processed. Cleanliness is a critical factor in preventing cross-contamination and safeguarding public health.

- Quality Control in Packaging

UV inspection lamps are also used to check the quality of food packaging. They help ensure that seals, labels, and packaging materials are intact. Since certain UV-reactive inks are used in labeling and packaging, the lamps can also help identify poorly applied labels or damaged packaging, preventing potential contamination.

Benefits of UV Inspection Lamps in Food Processing

Using UV inspection lamps in food processing offers numerous benefits:

- Increased Detection Capabilities: UV inspection lamps help detect contaminants that are invisible under normal lighting conditions, enhancing the sensitivity of food safety checks.

- Non-Destructive Testing: UV light does not alter or damage the food product, making it ideal for non-invasive inspections.

- Cost-Effectiveness: UV inspection lamps are relatively low-cost tools compared to other testing methods, such as microbiological testing, and provide quick results.

- Efficiency and Speed: UV inspection lamps allow for fast detection, speeding up the inspection process in busy food processing environments.

Key Features of UV Inspection Lamps

To maximize the effectiveness of UV inspection, it’s important to choose the right UV lamp for the application. Here’s a quick table summarizing the important features to consider:

| Feature | Importance | Description |

| Wavelength Range | Essential for fluorescence detection | UV-A lamps (320-400 nm) are typically used for inspection purposes. |

| Portability | Affects usability in various environments | Handheld models are preferred for flexibility and mobility. |

| Durability | Impacts lamp longevity and reliability | UV lamps should be built to withstand frequent use in food processing environments. |

| Intensity and Coverage | Determines inspection area size | Higher intensity lamps provide broader coverage and greater fluorescence visibility. |

| Power Source | Affects convenience and running costs | Rechargeable and battery-operated models offer greater flexibility. |

How to Use UV Inspection Lamps for Contaminant Detection

Using UV inspection lamps in food processing is relatively simple, but for maximum effectiveness, certain steps should be followed:

- Prepare the Area: Ensure that the area is dark or dimly lit to maximize the UV light’s effectiveness.

- Activate the UV Lamp: Turn on the UV inspection lamp and begin scanning surfaces or equipment.

- Inspect for Fluorescence: Look for any substances that fluoresce, such as bacteria, mold, foreign particles, or cleaning residues.

- Take Action: If contaminants are found, clean or disinfect the area, equipment, or product before further processing.

Q&A Section

Q1: What types of contaminants can UV inspection lamps detect?

A1: UV inspection lamps are excellent at detecting bacterial contamination, mold, foreign particles, and residues that fluoresce under UV light. Certain microorganisms, like E. coli, fluoresce under UV illumination, making them easier to spot.

Q2: Are UV inspection lamps safe to use in food processing environments?

A2: Yes, UV inspection lamps are safe when used properly. However, it’s important to wear protective gear, such as UV-blocking glasses, to prevent eye and skin exposure. Following proper safety protocols ensures safe use in food processing areas.

Q3: How effective are UV inspection lamps compared to traditional inspection methods?

A3: UV inspection lamps are highly effective in detecting contaminants that are invisible under normal lighting. While traditional inspection methods can identify visible contaminants, UV lamps add a layer of sensitivity by revealing microbial contamination and foreign particles that are otherwise hard to detect.

Q4: How often should UV inspection lamps be used in food processing?

A4: UV inspection lamps should be used regularly during food processing, especially after cleaning procedures, to ensure that surfaces and equipment are free of contaminants. They should also be used periodically to inspect packaging and food products before final release.

Q5: Can UV inspection lamps detect all types of contaminants?

A5: UV inspection lamps are effective at detecting contaminants that fluoresce, such as certain bacteria and foreign particles. However, they may not detect all types of contamination, especially if the contaminant does not fluoresce under UV light. For comprehensive contamination detection, UV inspection lamps should be used alongside other testing methods.

Conclusion

Incorporating UV inspection lamps into food processing operations enhances the ability to detect contaminants that are invisible under normal lighting. These lamps play a crucial role in ensuring food safety by revealing harmful bacteria, foreign particles, and residues that would otherwise go unnoticed. Whether for detecting contamination on food surfaces, ensuring cleanliness of equipment, or verifying the quality of packaging, UV inspection lamps are a cost-effective, non-invasive, and efficient solution for food safety professionals.

For businesses in the food processing industry looking to integrate UV inspection technology, consider theSunlonge UV inspection lamp, which offers high-intensity UV light for superior contaminant detection. With the right UV inspection lamp, food processors can maintain high-quality standards and safeguard public health by identifying risks early in the processing cycle.

CN

CN