Ultraviolet (UV) radiation is all around us – in the form natural sunlight. In industrial sectors, the non-visible light has numerous applications, from paint curing and non-destructive testing (NDT) to chemical analysis and counterfeit detection. On the light spectrum scale, UV bands can be found between gamma/x-rays and the visible light range.

Specifically, the short-wave UV range falls on the opposite side of infrared and microwaves, which are groups of long-wave bands. Measurements for UV waves range between 100 to 400 NM– sometimes reaching 430 NM for specific applications. At the high end of the UV range, the bands overlap with the visible spectrum (400+ NM), resulting in slightly visible ‘violet’ output.

The UV range is classified into three parts: UV-A, UV-B and UV-C. Each group has its own set of unique characteristics and applications.We mainly talk about the UV-A, which is widely used in the industrial application.

UV-A Light (and Black Light)

UV-A measures between 315 to 400 NM. It is considered to be the least intense and harmful out of the three UV bands. However, with long-wave characteristics, this type of light can reach deep into the human skin resulting in accelerated aging.

In industrial markets, UV-A lighting systems are mostly found in paint spray booths and manufacturing sites. The luminary is used to speed up the curing process, allowing businesses to boost productivity and production rates. During use, an operator applies a base coating on the surface, consisting of liquid monomers, liquid oligomers and photoinitators. UV-A bands are then administered to activate the molecules. The paint curing process takes roughly 30-125 seconds.

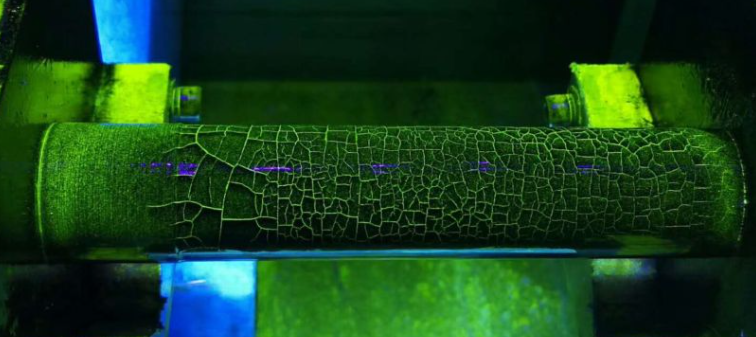

In NDT, UV-A light is heavily utilized. The testing method is effective in uncovering inconsistencies and cracks on surfaces or materials in a non-intrusive manner. Without bending or exerting large amounts of physical pressure on the surface, NDT is capable of keeping the object intact and free from damage during the testing process. In application, an individual applies liquid penetrants or fluorescent dyes on the surface. UV-A light is then applied to highlight inconsistencies on a micro level.

Based on the applications for UV-A light, the lamps must be equipped with robust features to streamline their application. In paint curing, shields are used around the light head to prevent light trespass and improve the intensity of the UV band. While in NDT, a cut-off component ensures stray UV bands exceeding 400 NM are blocked to reduce contamination.

When it comes to mainstream and commercial applications, UV-A fixtures are widely referred to as black lights or Wood’s lamp. Examples of applications include industrial NDT service and industrial fluid systems leaks detection. As the leading manufacturer for the ultraviolet products, Sunlonge can offer customers full sets of industrial UV lights for all kinds of different request. In the future, Sunlonge will keep rooted in this filed and offer more and more reliable industrial UV lamps for customers all over the world.

CN

CN