Fluorescent Leak Detection Dye; UV A/C Oils;Refrigerant UV Dye

Fluorescent Oils dye 3600

DESCRIPTIONS AND FEATURES

Fluorescent Oils dye 3600 is a concentrated solvent soluble dye containing high conjugate polycyclic compounds in a polyol ester oil system. The product is an amber colored liquid and has been found to be completely miscible in most petroleum or organic based products such as POE&PAG.The solvent is used in the product as a viscosity depressant and standardizing agent. Fluorescent Oils dye 3600 is applicable to POE/PAG lubricant, mineral oil lubricant, and also available for system using Poly Vinyl Ether (PVE) lubricant.

SL3600 leak detection fluorescent tracer dye typical property:

| Content | Data |

| Suitable wavelength for fluorescence inspection. | 365NM |

| Typical usage ratio(L) | 0.3—1.0ml |

| Solubility(Petroleum products) | Insoluble |

| Solubility (Oil) | Fully dissolved |

| Density(20 °C) | 0.85 |

| Flash Point | >85°C (212°F) |

| Ionic | Anionic |

| Stickiness | ≤60 |

| Seal Material Compatibility | All rubber, plastic and metal parts (including concentrated and diluted dye) |

Typical Uses

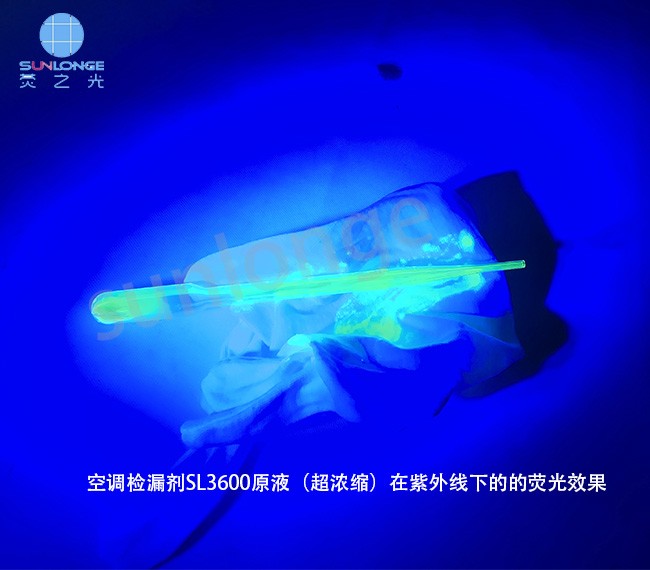

Fluorescent Oils dye 3600 can be used for leak detection in air conditioning systems. Applications include HVAC/R and Automobile air conditioning. This application requires addition of the fluorescent dye to the compressor oil or the refrigerant and subsequent examination of the A/C system using a high intensity black light. Leaks are easily detected with this system by the intense bright yellow fluorescence of the dye. This fluorescence is readily distinguished from the natural blue fluorescence found in some oils.

Application Recommendations

Introduction of the dye into the system can be carried out in one of two ways. Dye may be premixed with A/C compressor oil or refrigerant and added to the A/C system prior to the test or use specific injector to add fluorescent dye with system off or running.

Leakage is monitored during and after test by examining the A/C system with a high intensity black light. Leakage is readily detected by the presence of a bright yellow fluorescence caused by the presence of the dye.

Fluorescent Oils dye 3600 can remain safely in the system without harmful effects to A/C system. This makes it fast and easy to pinpoint leaks, confirm repairs and perform future preventive maintenance checks

Recommended Dosage

The following recommendations are provided as a starting point for typical applications. Actual dosage will depend on desired color strength as well as background color of base material.

Refrigerant(R134a/R-1234yf) 3 0/00

Synthetic lubricant 2%

Mineral lubricant 2.5%

Clean Up

The dye is easily removed from metal surfaces with common cleaner, or by dry wiping.

Storage

As a non-dangerous product, this product can be transported and stored as a common chemical. The recommended storage temperature for this material is between -10 and 400 C. Exposure to excessively low temperatures should be avoided as it may cause increased levels of precipitation. This product should be sealed in a cool dry place away from light

If product containers are kept sealed in a dry place away from light and extreme temperatures are avoided the shelf life of the material is greater than 3 years. The container should be tightly closed when not in use in order to prevent solvent evaporation.

Safe Handling Information

See Material Safety Data Sheet for complete list of…

- Hazardous ingredients

- Identified hazards

- First aid measures

- Fire prevention measures

- Accidental release measures

- Handling and storage precautions

- Recommended personal protection

CN

CN