Leak detection fluorescent dye:SL3200

Description and Features

SL3200 leak detection fluorescent dye is a concentrated solvent soluble dye containing fluorescent dye in a high flash hydrotreated naphthenic solvent system. The product is a dark colored liquid and has been found to be completely miscible in most petroleum or organic based products. The solvent is used in the product as a viscosity depressant and standardizing agent.

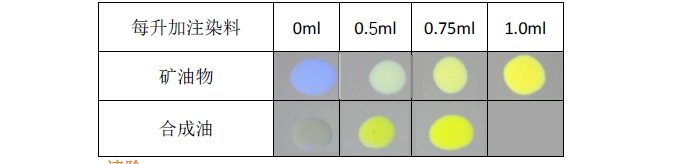

The picture below shows the effect of adding fluorescent agent to gasoline oil under ultraviolet light:

Typical Uses

SL3200 leak detection fluorescent dye can be used for detecting oil leaks in gasoline and diesel engines. This application requires addition of the fluorescent dye to the engine oil and subsequent examination of the engine using a high intensity black light. Leaks are easily detected with this system by the intense white-yellow fluorescence of the dye. This fluorescence is readily distinguished from the natural blue fluorescence found in some oils.

Application Recommendations

Introduction of the dye into the engine can be carried out in one of two ways. Engine oil and dye may be premixed and added to the engine prior to the engine test or dye may be added to the engine after the oil fill by adding the dye directly into the engine sump.

Leakage is monitored during and after the test; test or after the dynometer test by examining the engine with a high intensity black light (SUNLONGE UV LAMP emitting at 365 nm). Leakage is readily detected by the presence of a white-yellow fluorescence caused by the presence of the dye.

SL3200 leak detection fluorescent tracer dye typical property:

| Content | Data |

| Suitable wavelength for fluorescence inspection. | 365NM |

| Typical usage ratio(L) | 0.3—1.0ml |

| Solubility(Petroleum products) | Insoluble |

| Solubility (Oil) | Fully dissolved |

| Density(20 °C) | 0.85 |

| Flash Point | >85°C (212°F) |

| Ionic | Anionic |

| Stickiness | ≤60 |

| Seal Material Compatibility | All rubber, plastic and metal parts (including concentrated and diluted dye) |

Recommended Dosage

The following recommendations are provided as a starting point for typical applications. Actual dosage will depend on desired color strength as well as background color of the base material.

Hydraulic & Transmission: Fluids 500 to 2000 ppm

Car Engine Oils: 500 ppml

Diesel Engine Oils: 700 to 2000 ppm

SL3200 oil based fluorescent UV dye:

1) Car engine oils: *00 PPM. That is 1:2000. That means 1L oil dye can treat 2000L car engine oil in the detection.

2) Diesel engine oils: *00 to *000 PPM. That is * -*000. That means 1L oil dye can treat *000L diesel engine oil in the detection.

3) Gear oils: *000 -*000 PPM. That is */*000. That means *L oil dye can treat 1000L gear oil in the detection.

Remarks:Leak Detection — How It Works

It’s a simple fact: circulate refrigerant, oil, coolant, fuel, hydraulic fluid or automatic transmission fluid and sooner or later leaks will develop. Leaks are often virtually impossible to find with conventional methods until they result in expensive vehicle failure.

The fluorescent leak detection changes that. It quickly locates even the smallest and most elusive leaks, including intermittent and simultaneous multiple leaks that would otherwise be missed. The Tracerline method saves labor, money, and downtime, as it also conserves expensive refrigerant and fluids.

The leak detection utilizes a simple method that has only two basic parts. A high-intensity Tracerline ultraviolet or blue light lamp is teamed up with the appropriate Dye-Lite (for fluid leaks) or Fluoro-Lite (for A/C leaks) fluorescent tracer dye. The fluorescent dye is added to the system and circulated. The system is then inspected with the lamp. Since the dye collects at all leak sites, the lamp will show the precise location of every leak with a bright glow. The dye can remain in the system indefinitely and does not affect system components or performance.

CN

CN