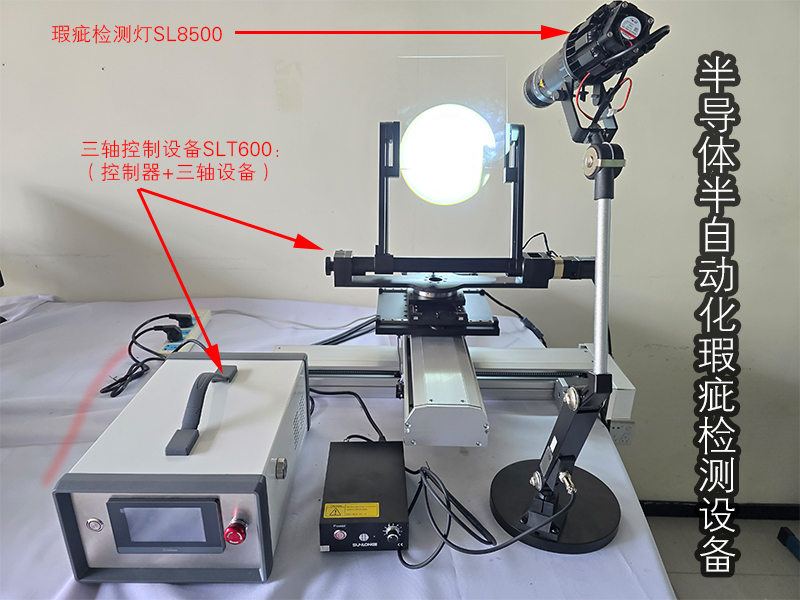

Sunlonge semiconductor semi-automatic inspection device, consists of the three-axis automatic automatic adjustment device SLT600(three-axis manual/electric rotary table+controller) and the wafer inspection lamp(generally with SL8500-GY). SLT600 rotary table adopts electric control, fast response speed, high accuracy,realizing complex motion control and efficient energy conversion, high stability and repeatability, detect the defects at minimal um size. Widely accepted by the semiconductor manufacturer.

Principle of semi-automatic defects inspection device:

The wafer inspection lamp SL8500 is with suitable LED light source. Through the multiple conversion of optical lens, SL8500 can emit the light with special wavelength and shine on the surface of work-piece. Then operators can detect the defects with the naked eyes, eg, dust, scraches, burrs, bump, ink and so on. The three-axis rotary table is running by the controller, which can comprehensively detect the defects of different positions, hands free.

Inspection procedure of semi-automatic defects inspection device.

The semiconductor material to be inspected is installed on the three-axis console. The wafer inspection lamp is placed in front of the material. The console has three exes, XYA. The controller can move the material up and down, left and right. So the material can be all-around through the shining of the wafer inspection lamp. Then the operator can detect the defects on the material surface.

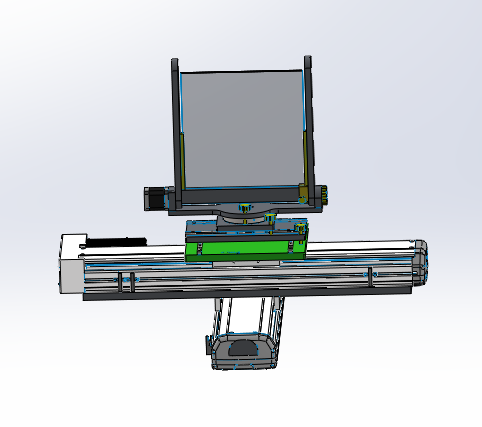

SLT600 three-axis manual, electric rotary table parameters:

Model: SLT600 rotary table.

- X/Y axis electric travel range: 500(±250)mm Z axis electric travel range: 250mm

- X/Y manual travel range: ±75mm Rotary hand adjustment: ±120°

Tilt hand adjustment: ± 90 °; Clamping hand adjustment: 100mm

- Rotary table size: 78 * 78CM, Weight 38KG Console: 38*25*16cm 8KG

Features of SLT600 manual, electric rotary table:

- The rotary table is made up of aluminum alloy, with precision-machined guide rail and transmission parts.

- Compact structural design, easy to operate, suitable for environments with limited space. The rotation is realized by manual adjustment, with high repeatability and precision

- Application: Widely used in scientific research, laboratories and other occasions with high requirements for precision and stability, such as optical experiments, precision instrument construction, etc.

CN

CN